Article Contents

Synthetic diamonds, made using High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD) methods, provide a more environmentally friendly option compared to traditional diamond mining. These techniques use fewer natural resources and generate less waste.

Moreover, synthetic diamond manufacturing frequently relies on renewable energy sources, lowering carbon emissions. This strategy resonates with consumers who value environmental sustainability.

Continued research will offer additional understanding of how these approaches are implemented throughout the sector, guaranteeing that synthetic diamonds continue to be a conscientious selection in the high-end gem industry.

Key Features

- Synthetic diamonds produce significantly less carbon per carat than natural diamonds, resulting in a smaller carbon footprint.

- The production of synthetic diamonds heavily relies on renewable energy sources, which helps decrease their environmental impact.

- Modern techniques in the manufacture of synthetic diamonds reduce water use and improve waste management and recycling processes.

- The HPHT (High Pressure High Temperature) and CVD (Chemical Vapor Deposition) methods used in the production of synthetic diamonds consume fewer resources and are more sustainable than conventional diamond mining.

- By implementing sustainable practices such as utilising renewable energy and minimising water and energy use, synthetic diamonds represent an environmentally conscious option in the luxury market.

Overview of Production Methods

Synthetic diamonds are created using two primary methods: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Both techniques mitigate the ethical and environmental concerns associated with natural diamond extraction. HPHT mimics the natural conditions in which diamonds form, applying intense pressure and heat to carbon sources. Despite its effectiveness, HPHT's significant energy and raw material requirements have prompted scrutiny concerning its sustainability.

In contrast, CVD synthesises diamonds by depositing layers from a gas mixture, mainly consisting of methane and hydrogen, in a controlled environment. Known for its precision, CVD is less resource-intensive, which lowers its environmental impact. This method's flexibility facilitates the tailoring of diamonds for specific uses, enhancing their functional value.

Both HPHT and CVD reflect a commitment to sustainable production and responsible resource use, catering to consumers who value environmental stewardship in luxury products. By employing these innovative technologies, synthetic diamond production not only provides an ethical alternative but also upholds conscientious consumption practices.

Energy Consumption Analysis

In assessing the environmental impact of synthetic diamond production, it is crucial to analyse energy consumption and the power sources used.

This analysis includes evaluating energy efficiency improvements and comparing the carbon footprints of synthetic and natural diamonds.

Such an examination ensures a comprehensive understanding of the industry's sustainability practices, emphasising efforts to minimise environmental effects.

Power Source Types

Lab-grown diamonds primarily use electricity, increasingly sourced from renewable energy, for their production. Utilising renewable sources like solar and wind power not only supports sustainable practices but also significantly reduces the environmental impact. This shift is vital in environmental impact assessments, highlighting a lower carbon footprint and improved ecological integrity.

The energy required to produce synthetic diamonds, mainly electrical, is significantly less than that needed for mining natural diamonds. By adopting renewable energy, lab-grown diamond manufacturers demonstrate a commitment to sustainability, offering consumers an ethical choice.

Energy Efficiency Measures

Assessments of energy efficiency in synthetic diamond production indicate that it consumes significantly less energy than traditional mining. The adoption of High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD) technologies not only reduces energy use but also integrates renewable energy sources.

This shift towards more sustainable practices reflects an industry commitment to reducing environmental impact and aligning with the values of environmentally conscious consumers. By focusing on these advanced, energy-efficient technologies, the synthetic diamond industry is moving towards a more sustainable model of operation, which supports the concept of responsible luxury appealing to ethically minded consumers.

This transition is crucial for the long-term sustainability of the diamond industry and is trusted by consumers seeking environmentally responsible options.

Comparison of Carbon Footprint

The environmental impact of lab-grown diamonds significantly differs from that of mined diamonds, primarily in terms of carbon emissions. Mined diamonds contribute approximately 57,000 grams of carbon per carat, which is substantially higher compared to the 0.028 grams per carat emitted by lab-grown diamonds.

This considerable difference underlines the environmental advantages of choosing lab-grown diamonds. Additionally, the production of lab-grown diamonds often relies on renewable energy sources, which not only reduces electricity use but also enhances their sustainability profile.

Consequently, lab-grown diamonds represent a more environmentally responsible choice, contributing positively to ecological sustainability by minimising carbon emissions and optimising energy use.

Water Usage Evaluation

Synthetic diamond production significantly reduces water usage compared to traditional diamond mining, reflecting its lower environmental impact. These lab-grown diamonds are created using advanced technologies that efficiently minimise water consumption and adhere to strict environmental standards focused on water conservation. Such practices not only decrease the demand for water but also prevent water pollution, thereby protecting local ecosystems.

Additionally, the facilities that manufacture synthetic diamonds have rigorous systems in place for water recycling and responsible waste management. These measures help to conserve water resources and prevent contamination of nearby water bodies, enhancing the sustainability of the process. By adopting these environmentally friendly practices, the synthetic diamond industry serves as a model for sustainable production, demonstrating how modern technology can align with environmental conservation. This commitment to reducing the ecological footprint of diamond production positions synthetic diamonds as a responsible choice for consumers who value both luxury and environmental stewardship.

Waste Generation Review

In the field of synthetic diamond production, managing byproducts efficiently is crucial for reducing environmental impact.

Recycling and reusing waste not only decrease waste volume but also promote sustainable manufacturing methods.

This discussion highlights these essential practices, emphasising their significance in making synthetic diamond production more environmentally friendly.

Management of Production Byproducts

Effective management of by-products is crucial in minimising the environmental impacts of synthetic diamond production. The processes of detonation synthesis and purification generate waste that, if not properly handled, can contribute to global warming and freshwater eutrophication. Implementing robust waste management strategies can significantly reduce the environmental footprint of these operations and promote sustainability.

Recycling initiatives, integrated within the environmental impact assessments, are key to sustainable by-product management. Such measures ensure that the pursuit of technological advancements in synthetic diamond production does not detrimentally affect the environment, aligning with the principles of environmental stewardship.

Waste Recycling Techniques

To reduce environmental impact, synthetic diamond manufacturers in the UK adopt several waste recycling methods aimed at enhancing resource use efficiency and decreasing waste production.

- Reusing solvents: This approach helps save on chemical usage and mitigates the emission of hazardous compounds into the environment.

- Recycling water: Treating and reusing water within the manufacturing cycle significantly reduces the water consumption of these facilities, promoting better resource management.

- Repurposing byproducts: Converting waste into useful products aids in the adoption of a circular economy model, maximising the use of materials and minimising waste.

These practices highlight the industry's commitment to sustainable operations and the conservation of natural resources, vital for preserving ecological balance and achieving environmental sustainability.

Carbon Footprint Consideration

Analysing the carbon footprint of synthetic diamonds indicates they have a much lower environmental impact compared to natural diamonds. While the production of lab-grown diamonds results in approximately 0.028 grams of carbon emissions per carat, natural diamond mining emits about 57,000 grams per carat. This vast difference highlights the environmental advantages of synthetic diamonds, which utilise less energy and often incorporate renewable energy sources in their production processes.

These sustainable practices not only reduce carbon emissions but also align with commitments to environmental protection. The use of renewable energy in synthesising diamonds enhances their sustainability and positions them as an attractive option in the luxury market focused on eco-friendliness.

The technology used in the production of synthetic diamonds minimises ecological impact, supporting the jewellery industry's shift towards more sustainable practices. By opting for synthetic diamonds, consumers and jewellers support environmental conservation and promote the longevity and health of our planet.

Enhancement of Sustainable Practices

Lab-grown diamonds represent a significant advancement in sustainable jewellery manufacturing. These diamonds are produced using methods that prioritise environmental protection, showcasing an evolution in the industry towards greener practices without sacrificing the quality or appeal of the diamonds. By adopting eco-friendly production techniques and responsible sourcing, lab-grown diamonds reduce ecological damage and cater to consumers who value ethical and environmental considerations.

- Renewable Energy Sources: Many producers utilise renewable energy sources such as solar or wind power, significantly decreasing their dependence on fossil fuels.

- Sustainability Certifications: Lab-grown diamonds are frequently certified by environmental standards organisations, verifying their low environmental impact.

- Environmental Compliance: Production facilities adhere to strict environmental regulations, underlining their dedication to sustainability.

These practices place lab-grown diamonds at the forefront of the environmentally conscious movement in the jewellery sector. Consumers who choose these diamonds support a tradition of environmental responsibility, helping to ensure that luxury and sustainability can exist side by side.

Frequently Asked Questions

How do synthetic diamonds impact the environment?

Synthetic diamonds help to reduce the environmental impact by decreasing energy usage and enhancing waste management, in contrast to conventional diamond mining which has a substantial ecological footprint.

How do you test for synthetic diamonds?

To identify synthetic diamonds, specialised laboratories use techniques such as spectroscopy and isotopic analysis. These methods accurately distinguish synthetic diamonds from natural ones by examining their unique characteristics and formation processes.

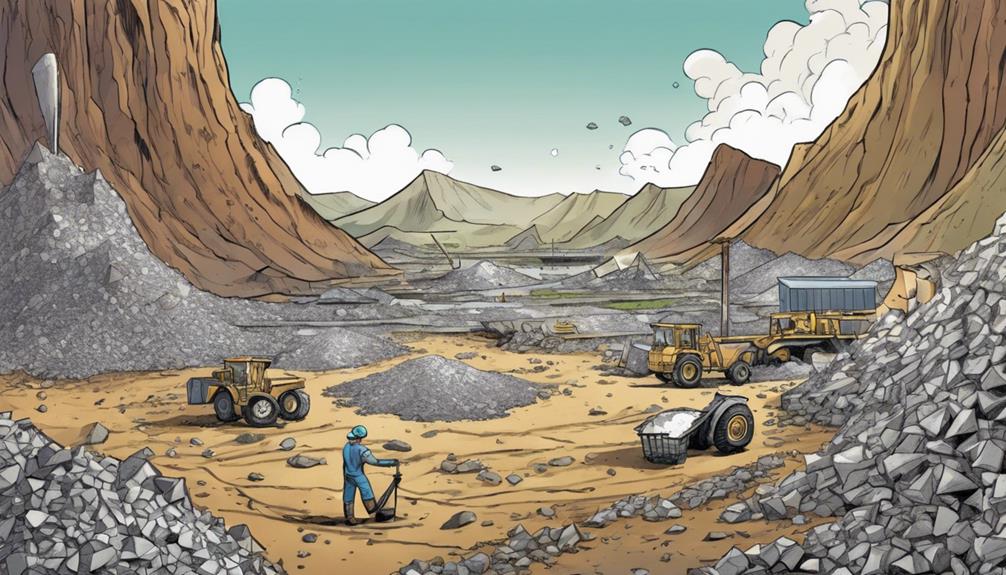

How does extracting diamonds affect the environment?

Diamond mining has significant environmental impacts, including deforestation, habitat destruction, and pollution. These activities disrupt local ecosystems, contribute to carbon emissions, and involve energy-intensive processes. Consequently, they compromise the sustainability of the affected regions.

Are Synthetic Diamonds Ethical?

Synthetic diamonds are regarded as ethical because they are created in controlled environments that usually guarantee fair labour practices, unlike some conventional diamond mining operations which may involve harsh working conditions and ethical concerns. These lab-grown diamonds offer a more humane alternative by sidestepping the environmental damage and possible human rights abuses associated with some natural diamond extraction methods. Therefore, synthetic diamonds make a positive contribution to both the social and environmental aspects of the gemstone market.

Summary

To summarise, lab-grown diamonds, although produced in laboratories, have a substantial environmental impact similar to natural diamonds because of their high energy consumption, water usage, and carbon emissions. Nevertheless, advancements in sustainable production methods offer hope for lessening these environmental consequences.

This development indicates a possible future where lab-grown diamonds are not just visually striking but also environmentally friendly. Striving to make diamonds that are as ethically sound as they are attractive continues to be a persistent challenge.