Article Contents

Lab-grown diamonds represent a significant improvement in the sustainability of jewellery production, notably in reducing water consumption compared to traditional diamond mining. These diamonds are produced using techniques such as High Pressure-High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Both methods are designed to be more water-efficient by incorporating advanced, closed-loop systems that recycle water.

Specifically, these processes reduce water use to approximately 18 gallons per carat, significantly lower than the 126 gallons required by conventional mining methods. This reduction not only lessens the impact on local water resources but also reflects a broader commitment to environmental responsibility in the jewellery industry.

This approach highlights the potential for ongoing improvements in the sustainability of jewellery manufacturing.

Key Points

- Lab-created diamonds require only 18 gallons of water per carat, significantly less than the 126 gallons needed for naturally mined diamonds.

- Utilising closed-loop systems, laboratories efficiently recycle water, drastically reducing waste.

- The application of advanced cooling technologies in the production of lab diamonds decreases water usage.

- Water recycling methods during the synthesis of lab diamonds preserve essential freshwater supplies.

- The adoption of sustainable practices in diamond laboratories minimises the impact on local aquatic ecosystems.

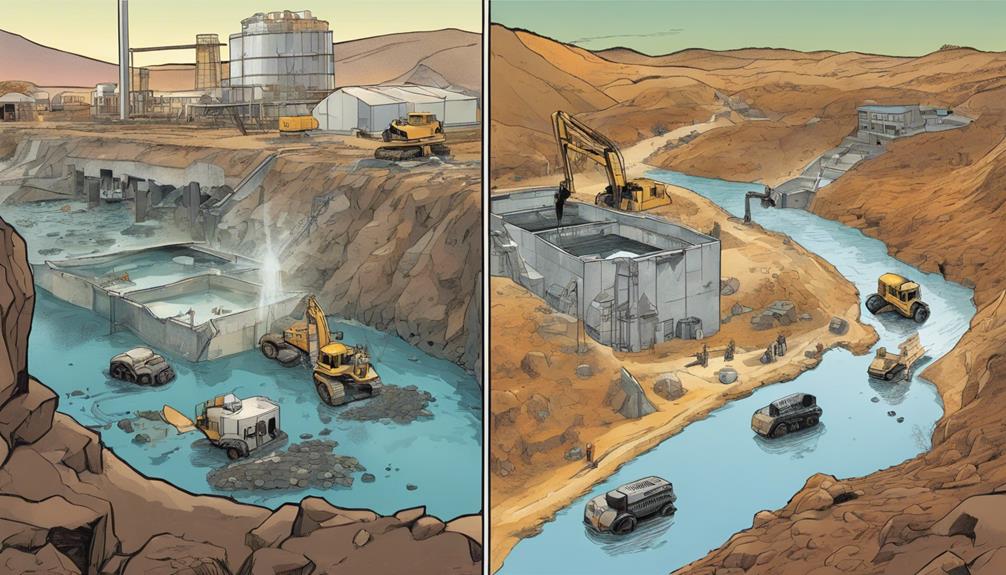

Water Usage in Traditional Mining

Traditional diamond mining uses significantly more water than the production of lab-created diamonds, consuming 6.8 times as much. This high water usage impacts the environment severely, particularly in water-scarce areas. Traditional mining techniques require large volumes of water for ore processing and dust control, which can heavily strain local water resources.

The extensive use of water in these mining processes not only causes immediate ecological harm but also threatens the long-term water availability for nearby communities. In areas where water is scarce, the added pressure from mining activities can exacerbate existing environmental and social challenges.

To address these issues, adopting more sustainable mining practices that minimize water use is essential. This shift is not only environmentally critical but also an ethical obligation to responsibly manage natural resources. Choosing sustainable alternatives and supporting less water-intensive methods in the diamond industry reflects a commitment to preserving vital environmental assets and promotes sustainability.

Lab Diamond Creation Process

Moving away from traditional diamond mining, lab-created diamonds are produced using two advanced techniques:

High Pressure-High Temperature (HPHT) and Chemical Vapor Deposition (CVD).

These methods represent significant technological advances in gemology and are notable for their efficiency and reduced environmental impact, particularly in terms of water use.

Comparing HPHT and CVD helps to understand how each contributes to sustainability in diamond production.

Synthetic Growth Techniques

Lab-grown diamonds are created using synthetic techniques such as High Pressure-High Temperature (HPHT) and Chemical Vapor Deposition (CVD). These processes mimic the conditions under which natural diamonds form, but occur in controlled laboratory environments. This method allows for precise control over the diamond's growth and significantly reduces the energy required compared to traditional diamond mining.

Resource Efficiency Comparison

Lab-created diamonds demonstrate superior resource efficiency in water usage compared to conventional mining methods. By employing advanced closed-loop systems, lab diamond production recycles and reuses water, significantly reducing environmental impact.

In contrast, conventional mining methods use approximately 126 gallons of water per carat, while lab-grown diamonds use only 18 gallons per carat. This substantial decrease highlights the sustainable practices of lab diamond production and illustrates a shift toward environmental responsibility in the jewellery industry, mitigating the heavy resource consumption associated with conventional diamond extraction.

Water Conservation Techniques

In the production of lab-grown diamonds, water conservation is critical. This is achieved through the use of efficient cooling systems that significantly minimise water consumption.

Recycling process water demonstrates a commitment to sustainability by maximising the use of each drop within the production cycle.

Additionally, advanced filtration technologies not only conserve water but also enhance its purity, thereby elevating the environmental standards of this forward-thinking industry.

Efficient Cooling Systems

Efficient cooling technologies in lab-grown diamond production are crucial for reducing water consumption and maintaining ideal temperatures necessary for diamond creation. These systems enhance energy efficiency and contribute to sustainability efforts in the industry.

Recycling Process Water

Recycling process water is a vital practice in the production of lab-grown diamonds, significantly reducing the reliance on fresh water sources and promoting sustainability. This approach effectively lowers water usage and highlights the industry's commitment to environmental stewardship.

By reusing water, lab diamond manufacturers minimise their ecological footprint, demonstrating a proactive step in reducing environmental impact. The recycling of process water plays a crucial role in preserving valuable water resources and supports environmentally friendly practices essential for sustainable development.

This method exemplifies how innovative manufacturing processes can align with ecological conservation, contributing to a sustainable future for both the jewellery industry and the broader environment.

Advanced Filtration Technology

Advanced filtration technology is crucial for sustainable water management in the lab-grown diamond industry. These high-efficiency systems conserve water by purifying and recycling it during diamond production.

By implementing water recycling, lab diamond facilities maintain closed-loop systems that significantly reduce water waste and environmental impact. Such measures not only boost the sustainability of the jewellery industry but also lessen reliance on fresh water resources, helping to mitigate water scarcity issues.

The adoption of advanced water filtration techniques demonstrates a commitment to environmental responsibility and the promotion of sustainable practices in jewellery manufacturing.

Comparative Analysis of Water Use

Lab-grown diamonds demonstrate a significant reduction in water consumption compared to traditional diamond mining, using up to 6.8 times less water. This efficiency contributes markedly to reducing the water footprint associated with jewellery production, presenting a more sustainable option in the industry.

Traditional diamond mining is not only water-intensive but also leads to environmental degradation, exacerbating water scarcity especially in arid areas. In contrast, the production of lab-grown diamonds incorporates advanced technologies that minimise both water wastage and pollution, thereby supporting water conservation initiatives.

Choosing lab-grown diamonds represents a shift towards environmentally responsible practices within the jewellery sector. This choice not only helps conserve vital water resources but also promotes sustainability in the fashion industry. The environmental advantage of lower water use in producing lab diamonds makes a compelling case for their increased adoption in modern jewellery collections.

Impact on Local Water Resources

The adoption of lab-grown diamond production significantly reduces water consumption, easing pressure on local water resources, especially in drought-prone areas. These facilities utilise water-efficient technologies, thereby conserving water and supporting both community welfare and environmental health.

In regions suffering from water scarcity, the lower water requirements of lab diamond production make more water available for essential uses such as agriculture and domestic needs. This is crucial in areas where traditional diamond mining has previously intensified water shortages. By employing closed-loop systems that minimise water waste, lab-grown diamond production exemplifies responsible resource management.

The environmental advantages of reducing water use are part of a broader commitment to sustainable practices that decrease the overall ecological footprint of diamond production. These practices not only help preserve the health of the planet but also enhance the sustainability of local ecosystems that are vulnerable to the impacts of resource-heavy industries.

Advancements in Sustainable Manufacturing

Lab-grown diamonds significantly reduce environmental degradation, using up to 6.8 times less water than traditional diamond mining methods. This innovation in sustainable manufacturing not only preserves vital water resources but also aligns with broader environmental conservation efforts. The adoption of such technologies in jewellery making demonstrates a crucial shift towards responsible production practices and highlights the importance of sustainable methods in reducing the industry's ecological footprint.

Choosing lab-grown diamonds directly contributes to water conservation and supports the global initiative for sustainable consumption. This choice reflects a commitment to environmental stewardship and promotes the health of our planet.

The development and implementation of sustainable manufacturing for lab diamonds represent a profound commitment to the well-being of future generations. It ensures that the aesthetics of jewellery are maintained without sacrificing the planet's resources, marking significant progress in the jewellery industry's pursuit of sustainability.

Benefits to Ecosystems and Wildlife

The adoption of lab-grown diamonds significantly reduces water consumption—by up to 90% compared to traditional mining methods—thereby benefiting local ecosystems and wildlife reliant on stable freshwater resources. This reduction in water use not only decreases the volume of water extracted from natural habitats but also lessens ecological disruption, aiding in the preservation of biodiversity by maintaining the balance between aquatic and terrestrial life forms.

Moreover, the diminished demand for water helps alleviate the effects of water scarcity and reduces pollution, which are often intensified by conventional diamond mining practices. This transition supports the protection of habitats, ensuring they remain uncontaminated and sustainable for diverse species. Choosing lab-grown diamonds reflects a commitment to ecological responsibility and promotes sustainable practices that benefit the planet.

Consumers selecting lab-grown diamonds indirectly support these environmental conservation efforts, contributing to the welfare of numerous species and the protection of their natural habitats. This choice not only fosters environmental health but also advocates for a holistic approach to conserving our natural world for future generations. By opting for lab diamonds, consumers demonstrate their commitment to ethical and sustainable practices within the jewellery industry, paving the way for a future that prioritises wildlife and ecosystem conservation.

Frequently Asked Questions

How are lab-grown diamonds more sustainable?

Lab-grown diamonds are more sustainable primarily because they have a significantly reduced carbon footprint compared to mined diamonds. Additionally, their production involves ethical practices that avoid the environmental degradation and labour issues associated with traditional diamond mining. This makes them a more environmentally and socially responsible choice for consumers focused on ethical consumption.

What are the benefits of lab-grown diamonds?

Lab-grown diamonds are ethically sourced and competitively priced, appealing to those who prioritise ethical and responsible choices. They offer a sustainable option in the jewellery industry, significantly reducing environmental impact compared to mined diamonds. This promotes responsible practices in diamond production and acquisition.

Can lab-grown diamonds get wet?

Lab-grown diamonds are highly resistant to water, preserving their appearance even after being exposed to water during durability tests or various cleaning processes. They are perfect for everyday use and remain unaffected by water.

How much energy does a lab-grown diamond use?

Lab-created diamonds typically require 250 to 750 kilowatt-hours of energy per carat. Manufacturers often use renewable energy sources to reduce the environmental impact of production, aligning with the preferences of environmentally conscious consumers.

Conclusion

When comparing traditional diamond mining with the production of lab-created diamonds, there is a significant difference in water consumption. Lab-grown diamonds use considerably less water, promoting a sustainable approach that lessens the impact on local ecosystems.

This method not only helps preserve our natural resources but also represents a shift in jewellery manufacturing towards environmental responsibility. Opting for lab diamonds reflects a commitment to sustainable practices essential for future generations.